Hydraulic Shears Machine Guide

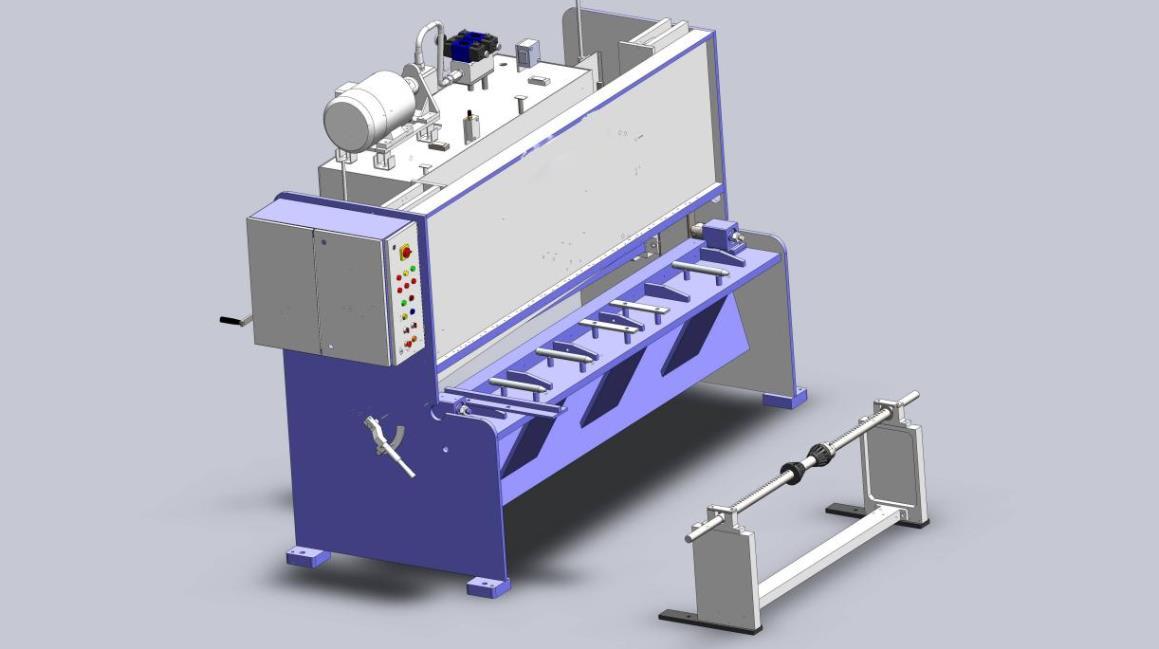

A hydraulic shearing machine is a machine that uses a movable upper blade and fixed lower blade and uses reasonable blade clearance to apply shearing force to metal plates of various thicknesses so that the plates can be broken and separated according to the required size.

A Shearing machine is a kind of forging machinery whose main function is metal processing. This machine is widely used in aviation, light industry, metallurgy, chemical industry, construction, shipbuilding, automobile, electric power, electrical appliances, decoration, and other industries to provide special machinery and complete sets of equipment.

What is a hydraulic shearing machine?

The compression cylinder of the hydraulic shearing machine is driven by the hydraulic system to compress the steel plate, and the left and right cylinders drive the blade to move up and down.

The upper blade on the blade holder and the lower blade fixed on the blade holder adopt a reasonable blade clearance. The shear force acts on sheet metal of various thicknesses. And split the shears according to the size of the desired break.

Hydraulic shears are widely used in various metal materials to meet various direct shearing needs. Mainly used in steel manufacturing, shipbuilding, automobile, container manufacturing, switchgear, machinery manufacturing, light industry, and other industries.

The working principle of the hydraulic shearing machine

As we said at the beginning of the article, sheet metal shearing is achieved by the movement of the upper and lower blades driven by the hydraulic system.

Different types of hydraulic shears

Shears can be divided into two categories: hydraulic shears and mechanical shears.

Due to the high energy consumption and noise of mechanical shears, hydraulic shears are more widely used.

According to the movement of the tool holder, the hydraulic shears can be divided into:

Hydraulic pendulum shears

Hydraulic guillotine shears

Advantages of hydraulic shears

A big advantage of hydraulic shears compared to older shears is that they are controlled by a series of codes during actual operation. There are many kinds of these codes. They are mainly produced by various permutations and combinations of characters. It depends on the application required to formulate the code for the specific job. One of the great advantages of controlling hydraulic shears in this way is that the orientation, speed and strength of the machine can be controlled more accurately. The concept of numerical control is to use computer programming to realize machine operation through the combination of numbers.

In the positioning direction, the hydraulic shearing machine has very obvious advantages. When the machine rotates, the adjusting rod can rotate along the central axis without a dead angle, and the machine has no loud noise, which enables the operator to work in a quiet environment without affecting the working mood and physical health of the person. The production material is high-strength stainless steel, which has good corrosion resistance and strength and can still maintain a high degree of stability in environments with large vibration amplitudes. The operation method is simpler and easier to learn. It needs computer talent to operate it. Moreover, this machine is not only practical but also beautiful in appearance. Great strides have also been made in security protection.

Hydraulic shears come with sturdy self-defense fencing. In the event of a machine failure, a fence separates the operator from the machine. The adjustment of the light also greatly increases the speed. It can quickly move the light and find the correct position, allowing people to see the specific work situation more clearly, which will bring more convenience to the production process and machine operation.

Application of hydraulic shearing machine

Hydraulic shears are widely used in decoration, electrical appliances, electric power, automobiles, ships, aerospace, and other fields.

In the field of decoration, hydraulic shears are widely used. It is generally used in conjunction with a bending machine to complete the production of stainless steel doors and windows and the decoration of some special places.

In the field of electricity and electricity, hydraulic shears can cut sheets into different sizes, and then re-process them by bending machines, such as electrical cabinets, refrigerators, air conditioner casings, etc.

In the field of automobiles and ships, a slightly larger hydraulic shearing machine is generally used, which mainly completes the shearing of the plate, and then performs secondary processing, such as welding and bending.

In the aerospace field, high precision is generally required. CNC hydraulic shearing machine and electro-hydraulic synchronous CNC bending machine can be selected, which are accurate and efficient.

Hydraulic shears and bending machines are more or less used in other fields and play an important role in related fields. If you want to buy hydraulic shears, please contact us.

Hengli is a professional custom hydraulic shears manufacturer. The main products are synchronized with the world's advanced technology, and are widely used in the pillar industries of the national economy such as automobile manufacturing and parts processing, iron and steel metallurgy processing, electric power, and metal packaging. The company aims to become a technology pioneer and market leader in the metal blanket forming industry, insists on innovation, builds a brand, and prospers China's equipment manufacturing.