The Composition of the Shearing Process of the Silicon Steel Sheet Slitting Line

The silicon steel shearing line, as the name suggests, is a longitudinal shearing line designed for the design of silicon steel sheet and strip steel. Hengli has a professional silicon steel coil design scissors production line, customized production.

At present, slitting lines can be divided into two categories in terms of cutting technology.

1. The slitting line of the cutting process.

2. The slitting line of the drawing and shearing process.

The slitting wire shearing process is a backward technology that has been used since the 1960s. This method of cutting quality is difficult to guarantee. The shearing process of the silicon steel sheet slitting line means that the silicon steel sheet advances under the action of the feeding roller, and then is sent to the disc scissors. The speed of the scissors and the feed roller line should be consistent. This process may cause the silicon steel sheet to bend between the feed roller and the scissors. When this phenomenon is serious, the silicon steel sheet will even roll up with the direction of rotation of the knife.

The stretching and shearing process of the longitudinal shearing line of the silicon steel sheet is that the silicon steel sheet moves forward under the action of the stretching roller, and the disc scissors are passively cut. Since the line speed of the drawing roller is slightly higher than that of the slitting, the silicon steel sheet is always kept straight between the drawing roller and the disc knife and is in the state of drawing and shearing to ensure the cutting quality.

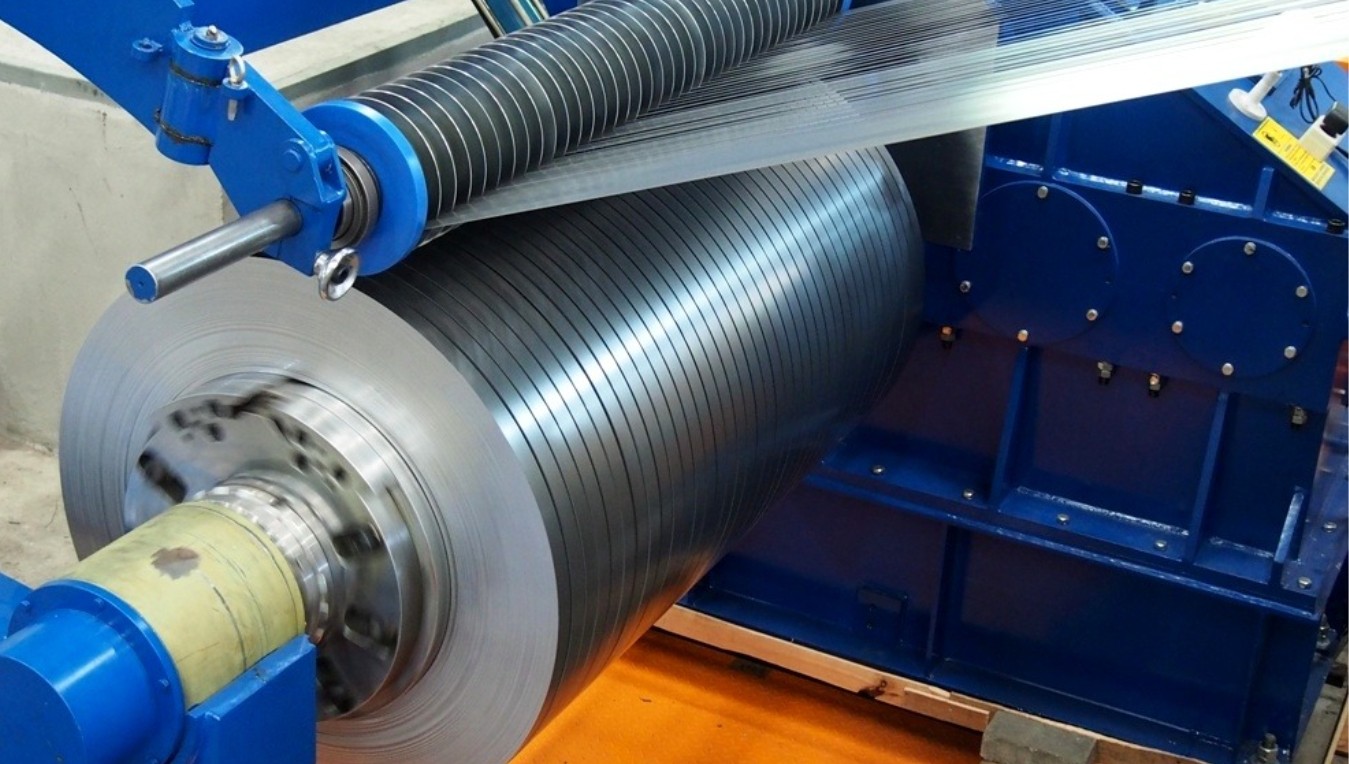

The silicon steel slitting line is mainly composed of the following equipment: uncoiler, slitting machine, waste edge machine, pressing device, winding machine, etc.

Coil slitting lines are used for trimming and discharging. By turning the screw pair of the handwheel, the sliding sleeve on the main shaft is driven, and the sliding sleeve drives the roller to expand and contract through the connecting rod. Also can use the hydraulic transmission to finish the above-mentioned action. The slitting machine is used for the longitudinal cutting of coils. The waste edge machine is used to recycle the excess edge material. The pressing device is used to assist the winding machine to coil the slitting silicon steel coil. Finally, complete the customer's production requirements.

The steel coil slitting line is suitable for steel coils of various specifications. The steel strip slitting line is used to cut the metal coil into the required narrow width through decoiler, pre-leveler, shearer, slitting machine, winder, and other processes for pipe welding or other stamping lines. It has the advantages of a reasonable layout, convenient operation, a high degree of automation, and high production efficiency.

The coil slitting line is suitable for processing cold-rolled, hot-rolled coils, silicon steel coils, stainless steel coils, colored coils, aluminum coils, and various coated coils. The slitting line is widely used in various industries such as automobiles, containers, household electrical appliances, food packaging, building materials, etc.

The 0.3-3.0 steel coil slitting line is suitable for various specifications of steel coils with a thickness of 0.3-3.0mm and a width of 500-2000mm. The coil slitting line can produce HR CR PPGI GI AL CU.

Cut-to-length metal steel is suitable for coils of various specifications. The cross-cut steel is used to cut the metal sheet into the required width and length from the coil through the uncoiler, uncoiler, cutting to length, slitting, packaging, and other processes. It has the advantages of a reasonable layout, convenient operation, a high degree of automation, and high production efficiency.

This metal cut-to-length consists of a feeding and cutting, uncoiler, pre-straightening machine, hydraulic ring bridge, deviation corrector, final straightening machine, servo length measuring instrument, steel shears to length, belt conveyor, reverse unloader, stacker Stacker, unloading truck, servo drive system, hydraulic system, etc.

The above briefly introduces the composition of the shearing process of the silicon steel sheet slitting line. If you want to order a silicon steel sheet shearing device, please contact us.

Hengli is a professional custom silicon steel shearing equipment manufacturer. Founded in 2005, it is a national high-tech enterprise specializing in the R&D and manufacturing of high-end industrial automation equipment. It is one of the main suppliers of sheet metal cutting and forming automation equipment in China. The main products are synchronized with the world's advanced technology and are widely used in the pillar industries of the national economy such as automobile manufacturing and parts processing, iron, and steel metallurgical processing, electric power, and metal packaging.