The Difference Between the Silicon-steel Cross Cutting Line and the Silicon Steel Slitting Line

The silicon steel sheet shearing device is a mechanical device for cutting steel plates and other metal materials. It is commonly used for the precision cutting and trimming of metal components in industrial settings. The device usually consists of a hinged frame with two sharp blades mounted on it. The blades are driven by electric motors. The blades are easily cut through steel and other metallic materials, creating precise and intricate shapes. This equipment is used in a wide range of industries from automotive manufacturing to aerospace engineering.

The silicon steel sheet shearing device usually includes a transverse cutting line and a vertical cutting line. Horizontal cutting wires are used for making long cuts, while vertical cutting wires are used for shorter, more precise cuts. Both types of wire can be adjusted to the desired cutting width and angle. So what's the difference between them? Read on to learn more.

What is a Silicon Steel Crosscut Line

Silicon steel cross-cutting line is a special cutting line for the fast and accurate cutting of silicon steel sheets. It usually consists of a motorized platform that holds the silicon steel sheet in place and two blades that can be adjusted to the desired angle and depth. The blades are then operated by an automatic control system to ensure precise cuts every time.

Silicon steel cross-cutting lines are often used in the manufacturing process as they provide a high level of accuracy and efficiency. They are also relatively easy to set up, as they require minimal setup time compared to other types of cutters. Additionally, they can be used in a wide range of applications from machining to sheet metal forming.

Due to the closed design, the operation of the silicon steel cross-cutting line is also very safe. This means the operator is not exposed to the heat and forces generated during the cutting process. In addition, the position of the blade can be adjusted for easier access and increased safety.

What is a Silicon Steel Slitting Line

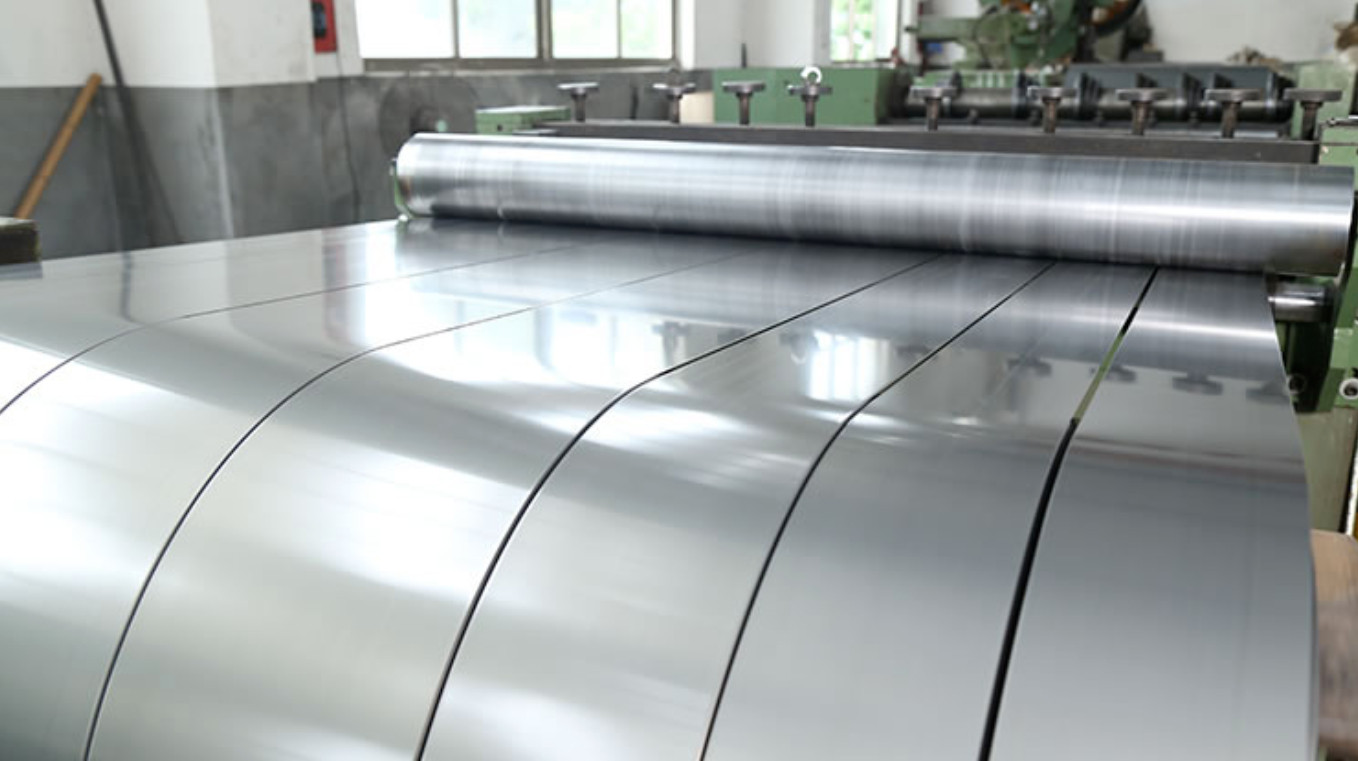

Silicon steel slitting line refers to a vertical cutting specially used for processing silicon steel parts and processes silicon steel materials into smaller objects. Silicon steel slitting lines can be used to create parts of different precision and complexity according to customer needs, and are most commonly used in the manufacture of mechanical components, metal parts or refrigeration device components.

The processing method of silicon steel vertical tangent line can be divided into two steps: using water-cooled or air-cooled cutters to cut silicon steel materials into multiple thin slices, and then using machine tools for complete processing. This method can guarantee the quality of silicon steel vertical tangent products and can achieve high precision and good surface flatness.

What is the Difference Between the Silicon Steel Crosscut Line and the Silicon Steel Slitting Line

Both the silicon steel crosscut line and the silicon steel slitting line use special tools to interrupt and cut the raw materials. Both are used to produce parts. The difference is that the purpose of the silicon steel transverse cutting line is to turn large pieces of material into several thin parts, while the purpose of the silicon steel crosscut line is to process large pieces of material into small parts. In terms of application, both silicon steel crosscutting lines and silicon steel slitting lines can be used in the manufacture of mechanical engineering parts.

In terms of price, the price of silicon steel crosscut wire and silicon steel slitting line may vary due to the material, shape, and size of silicon steel. But in general, silicon steel crosscutting lines are usually cheaper than silicon steel slitting lines, because silicon steel crosscutting lines only need one tool to complete the work, while silicon steel slitting lines need multiple tools to complete.

The processing methods of the two are also different. The horizontal cutting line of silicon steel is usually completed by a water-cooled or air-cooled cutting machine, while the vertical cutting line of silicon steel uses the cutting machine to cut the raw material into thin slices, and then uses the machine tool for complete processing.

The selection of silicon steel cross-cutting line and silicon steel slitting line should be considered according to specific application scenarios. If you need to produce larger components, you can choose a silicon steel crosscut line; if you need to produce smaller components, such as mechanical parts, metal parts, or refrigeration plant components, you can use a silicon steel cross-cutting line. Reasonable selection of silicon steel cross-cutting lines and silicon steel slitting lines can improve work efficiency and reduce production costs.

The above introduces the difference between the silicon steel cross-cutting line and the silicon steel slitting line. If you have any questions or you want to buy a silicon steel shearing device, please contact us.

HENGLI is a professional custom silicon steel shearing devices manufacturer. The main products are: automotive outer panel stamping and forming automation systems, online robots, high-precision sheet metal automatic shearing devices, industrial automation online detection systems, electrical automation devices, and overall automation control solutions. The main products are synchronized with the world's advanced technology and are widely used in the pillar industries of the national economy such as automobile manufacturing and parts processing, iron and steel metallurgical processing, electric power, and metal packaging.