Predictive Maintenance of Slitting Equipment

In today's industrial environment, where efficiency and uptime are critical, the concept of predictive maintenance has become a game changer. Especially in industries such as manufacturing, where downtime can result in significant financial losses, predictive maintenance provides a proactive approach to equipment maintenance. In this article, we take a deep dive into the field of predictive maintenance as applied to slitting equipment, exploring its benefits, challenges, and implementation strategies.

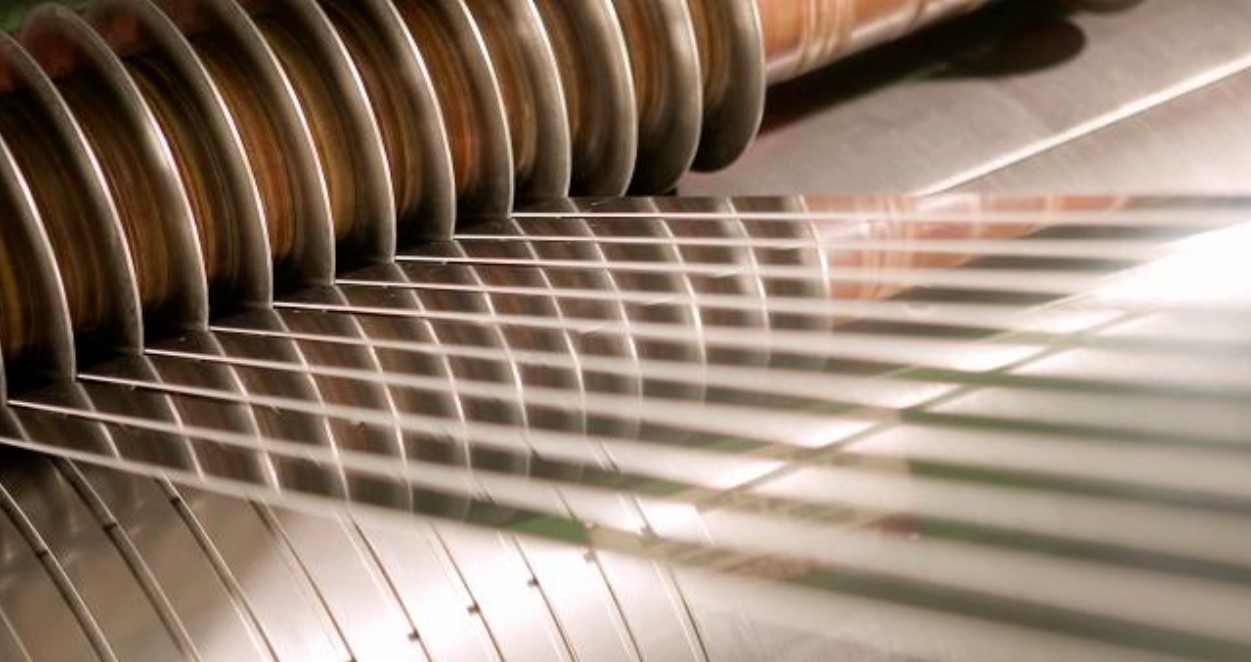

Learn About Slitting Equipment

Slitting equipment, also known as slitting machines or slitting machines, are specialized equipment used in various industries to precisely cut and resize materials such as paper, plastics, metals, and textiles. These machines play a vital role in converting large rolls of material into narrow strips or rolls of specific widths, catering to the diverse needs of end-users in different industries. The slitter slits the material lengthwise through a series of cutting blades or rotating knives, while a tension control mechanism ensures uniformity and accuracy in the process. The versatility of slitting equipment allows customization of cutting parameters, including width, length and speed, making it indispensable in manufacturing, packaging, printing and converting applications.

How to Preventatively Maintain Slitting Equipment

Implement a Condition Monitoring System: In order to predictively maintain slitting equipment, it is critical to implement a condition monitoring system to continuously collect data on machine performance and health. These systems can include sensors for monitoring parameters such as vibration, temperature, pressure and lubrication levels. By collecting real-time data on equipment condition, operators can detect early warning signs of potential problems and take proactive steps to resolve them before they escalate.

Leverage Predictive Analytics and Machine Learning Algorithms: Once data is collected through a condition monitoring system, predictive analytics and machine learning algorithms must be leveraged to analyze the data and identify patterns that indicate impending failure. Machine learning algorithms can learn from historical data to predict future equipment behavior and predict maintenance needs. By leveraging predictive analytics, operators can schedule maintenance activities at the optimal time, minimizing downtime and maximizing equipment uptime.

Setting Thresholds and Alarms: In predictive maintenance of slitting equipment, thresholds and alarms must be set based on sensor data analysis. Thresholds can be established for key parameters such as vibration levels, temperature changes or oil contamination levels. When these thresholds are exceeded or abnormal patterns are detected, alerts are triggered to notify maintenance personnel, allowing them to promptly investigate the problem and take preventive measures before equipment failure occurs.

Implement a Predictive Maintenance Strategy: A predictive maintenance strategy for slitting equipment involves using insights from data analytics to develop proactive maintenance plans tailored to the specific needs of each machine. These programs may include tasks such as lubrication, alignment adjustments, blade sharpening or replacement, and critical component inspections. By prioritizing maintenance activities based on predictive insights, operators can optimize the life of their slitting equipment, minimize downtime and reduce overall maintenance costs.

Advantages of Predictive Maintenance for Slitting Equipment

Minimize Downtime: One of the significant benefits of predictive maintenance of slitting equipment is minimizing downtime. By continuously monitoring the condition of critical components and identifying potential issues before they cause failure, predictive maintenance allows operators to schedule maintenance activities during planned downtime. This proactive approach helps avoid unexpected failures and ensures that slitting equipment remains operational when needed, maximizing overall production uptime.

Optimized Maintenance Schedules: Predictive maintenance enables operators to optimize maintenance schedules based on the actual condition of the slitting equipment rather than predetermined time-based intervals. By analyzing the data collected from sensors and using predictive analytics, operators can determine the best time to perform maintenance tasks such as blade sharpening, alignment adjustments or lubrication. This targeted approach minimizes unnecessary maintenance and maximizes the efficiency of maintenance operations, thereby reducing costs associated with labor, materials and equipment downtime.

Extended Eequipment Life: Predictive maintenance helps extend the life of your slitting equipment by detecting and resolving potential problems early. Regularly monitoring equipment condition enables operators to identify wear, degradation, or emerging failures before they escalate into more serious problems. Timely intervention, such as replacing worn parts or adjusting operating parameters, can help prevent premature equipment failure and extend the service life of the slitter. This not only reduces the frequency of expensive equipment replacements, but also increases the overall reliability and performance of the equipment.

Cost savings: Predictive maintenance can save significant costs on slitting equipment. Predictive maintenance helps reduce operational disruptions and associated production losses by minimizing unplanned downtime, optimizing maintenance schedules, and extending equipment life. Additionally, proactive maintenance interventions based on predictive insights can prevent costly repairs or catastrophic equipment failures, saving money on emergency repairs and replacement parts. Overall, the cost savings achieved through predictive maintenance help make your slitting equipment more profitable and competitive in the long run.

Challenges and Limitations of Predictive Maintenance

While predictive maintenance offers compelling benefits, it also creates challenges and limitations. A significant barrier to adoption is the initial investment required to implement sensor networks, data infrastructure, and analytics capabilities. Additionally, integrating predictive maintenance systems with existing operational processes and workflows can be complex and time-consuming.

Another challenge is the need for skilled personnel who can interpret the data and implement maintenance strategies based on predictive insights. Therefore, organizations must invest in training and upskilling their workforce to maximize the benefits of predictive maintenance.

In Conclusion

In summary, predictive maintenance represents a paradigm shift in the way maintenance tasks are handled in industrial environments, including slitting equipment. By harnessing the power of data and analytics, predictive maintenance enables proactive intervention to minimize downtime, optimize maintenance costs and extend the life of equipment. While challenges remain, the benefits of predictive maintenance far outweigh the obstacles, making it a compelling strategy for organizations seeking to improve operational efficiency and competitiveness.

The above briefly introduces the benefits and importance of predictive maintenance of slitting equipment. If you want to know more or you are looking for a slitting machine manufacturer, please contact us.

Hengli is a leading slitting machine manufacturer known for its commitment to innovation and cutting-edge technology. The company's main product series are seamlessly integrated with the world's most advanced technologies and are widely used in key areas of the national economy such as automobile manufacturing and parts processing, steel and metallurgical processing, electric power, and metal packaging. With the vision of becoming a pioneer in the metal felt molding industry, Hengli is unswervingly committed to innovation and brand building to promote the prosperity of China's equipment manufacturing industry. Hengli puts innovation first, unswervingly focuses on technological progress, and strives to build itself into a technology pioneer and market leader, promoting the progress of China's equipment manufacturing industry, while setting new standards for quality and performance in the global market.