Accuracy Advantage: How Silicon Steel Shear Lines Outperform Traditional Methods

In metal fabrication, precision is crucial. At Hengli, we know that the quality of the final product is a direct reflection of the accuracy and efficiency of the manufacturing process. That's why we've invested in the latest technology to ensure our silicon steel shearing lines outperform traditional cutting methods and set new standards in the industry.

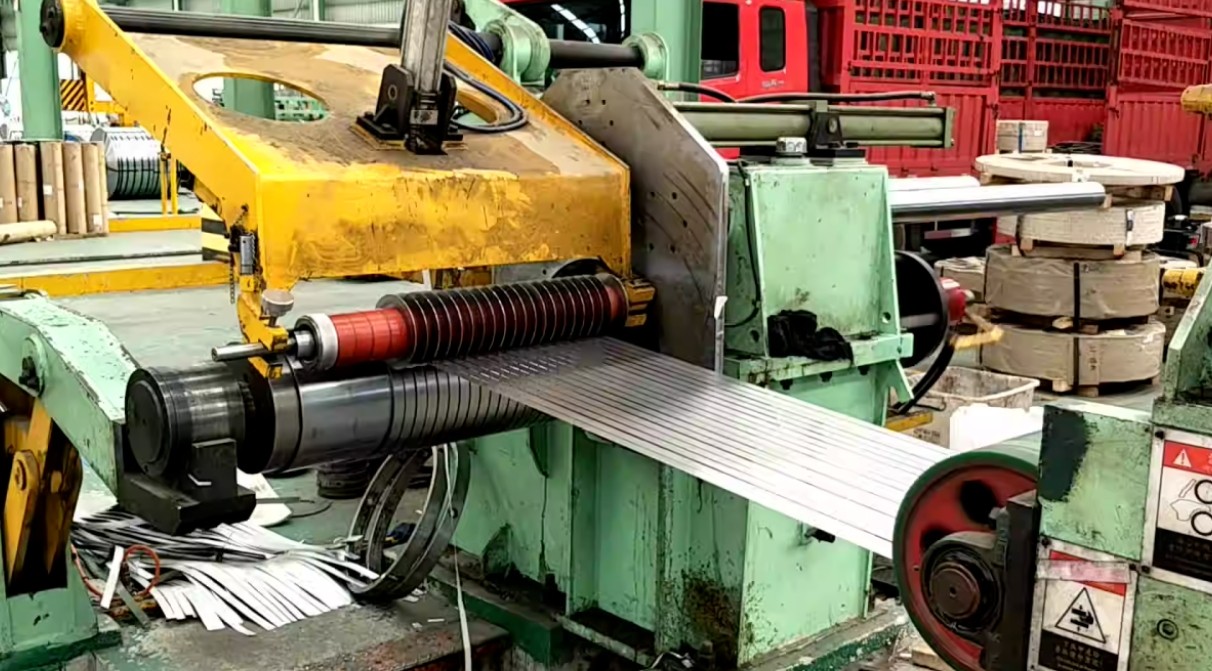

Advantages of Silicon Steel Shearing Line

In the world of metal fabrication, traditional cutting methods have been the cornerstone for decades. While they have served their purpose, they have inherent limitations that hinder efficiency and precision. These methods often result in lower accuracy, resulting in more wasted material and longer production times. However, the emergence of Hengli's silicon steel shearing production line provides a transformative solution to these challenges. By leveraging cutting-edge technology and innovative engineering, Hengli's systems redefine the standard for precision and efficiency in metal fabrication. It tackles the shortcomings of traditional methods head-on, delivering unparalleled accuracy and significantly reducing material waste.

With Hengli's silicon steel shearing lines, manufacturers can achieve significant efficiency gains while maintaining the highest quality standards. This innovative solution streamlines production processes, minimizes downtime and maximizes output. By optimizing cutting accuracy and minimizing material waste, Hengli helps manufacturers become more competitive in the market. The result is a paradigm shift in metal manufacturing, where precision and efficiency converge to drive greater profitability and success.

Improve Accuracy for Optimal Performance

At the forefront of cutting-edge technology, our state-of-the-art cutting lines are engineered to deliver unparalleled precision. These cutting lines combine advanced control systems and precision components to set new standards for manufacturing precision. Unlike traditional methods, our cutting lines can achieve tolerances that exceed expectations, ensuring every cut is executed with meticulous precision.

This extraordinary precision is more than just a feature; it's the cornerstone of our commitment to quality and performance. Our cutting lines cut with extreme precision every time, minimizing the margin of error and ensuring consistency and uniformity in every product. Whether molding complex parts or handling high-volume production, our cutting lines optimize precision to improve performance and deliver superior results.

Maximize Efficiency and Reduce Waste Efficiency

The core of Hengli silicon steel shearing production line is the unremitting pursuit of efficiency. By implementing cutting-edge automation technology, we have revolutionized the cutting process, minimizing the possibility of human error and unlocking unprecedented levels of efficiency. By automating complex cutting tasks, our production lines speed up production times, allowing us to meet the most demanding deadlines with ease.

This commitment to efficiency goes beyond just speeding up production times; it also yields tangible benefits in terms of waste reduction. With cutting-edge precision-driven automation, our silicon steel shearing lines minimize material waste. By optimizing the cutting process, we ensure that every material is fully utilized, resulting in significant cost savings for our valued customers. This dual focus on efficiency and waste reduction not only improves our operational efficiency, it also emphasizes our dedication to sustainability and responsible manufacturing practices.

Quality Assurance and Consistency

Ensuring high quality standards is vital in manufacturing, and silicon steel shearing lines are a beacon of excellence in this field. Known for their unwavering commitment to precision, these cutting lines adhere to strict quality standards and unparalleled consistency. Through meticulous engineering and advanced control systems, each cut is executed precisely, leaving minimal room for variation or error. This unwavering dedication to quality assurance ensures that every finished product produced on the silicon steel shearing line meets the highest standards of excellence.

Furthermore, the reliability and consistency offered by silicon steel shearing lines go beyond just adhering to quality standards; they foster trust and confidence among customers. Knowing that each product is crafted with precision and care can provide a sense of reassurance, reinforcing the manufacturer's reputation as a reliable and trustworthy partner. With every product produced to exacting specifications, manufacturers can build a reputation for excellence in their industry, positioning themselves as leaders in their fields.

In Conclusion

To sum up, choosing Hengli's silicon steel shearing production line means embracing the future of the manufacturing business dominated by precision and efficiency. As a specialist silicon steel shearing line manufacturer, our unwavering dedication to excellence and relentless pursuit of innovation set us apart, ensuring we not only meet but exceed industry standards. With Hengli, customers experience the transformative power of Hengli differentiation, with every cut executed with unparalleled precision and every production process streamlined for optimal efficiency.

By choosing Hengli's silicon steel shearing line, the manufacturer has taken its metal fabrication process to new heights. Our cutting-edge technology and unwavering commitment to quality ensure that every product is crafted with care, instilling confidence in our customers and building a reputation for excellence in the industry. Together with Hengli, the future of manufacturing will be characterized by precision, efficiency and unparalleled quality, laying the foundation for unprecedented success and growth. If you are looking for silicon steel shearing wire manufacturers, welcome to contact us.