The Importance of Maintenance to Maintain the Smooth Operation of the Silicon-Steel Cross Cutting Line

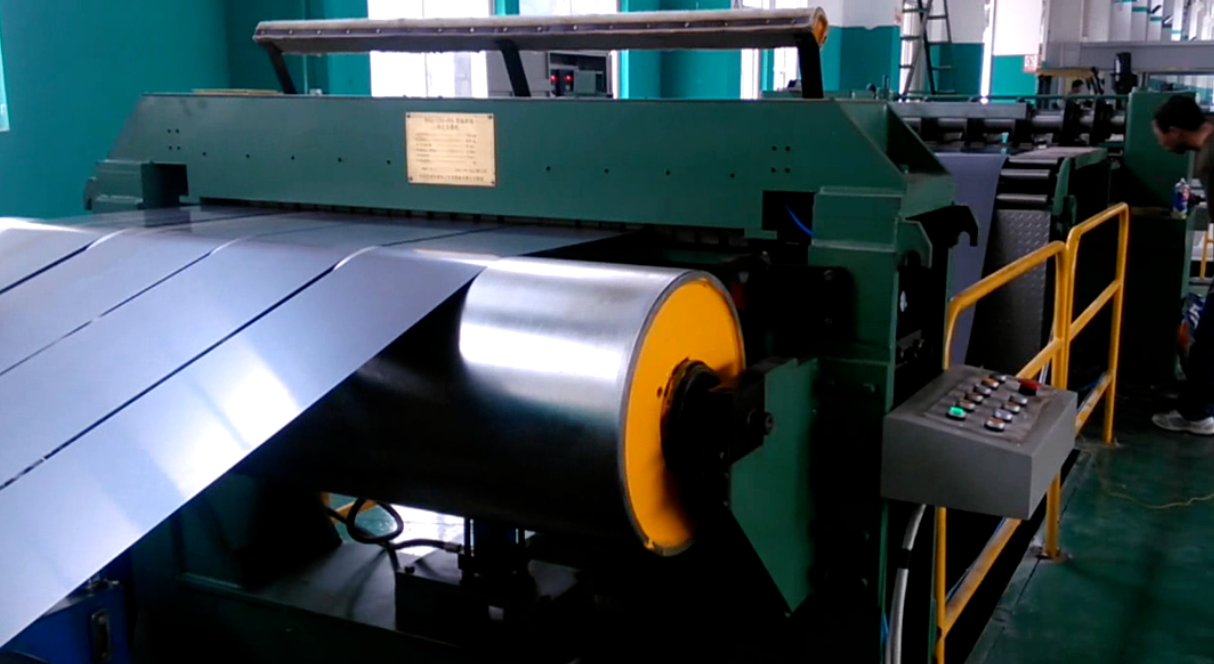

In today's industrial environment, the smooth operation of equipment such as silicon steel trantangent is crucial to maintain production efficiency and minimizing downtime. These production lines are an integral part of the production of silicon steel, which becomes an important material in transformers and motors because of its magnetic properties. Here, we explore in depth why maintenance plays a key role in ensuring that these systems operate perfectly.

Understand the Role of Maintenance in Operational Continuity

Maintenance is the key to ensuring operational continuity in the industrial environment, especially in the field of silicon steel cross-tangent systems. By complying to structured maintenance agreements, companies can proactively address potential problems, prevent unexpected downtimes, and maximize equipment performance efficiency. This method not only extends the service life of the machine but also maintains consistent output quality, thereby facilitating a seamless production process. Periodic maintenance activities include precautions such as routine inspections, timely maintenance, and active replacement of components, all of which collectively help to maintain optimal operational performance. With these efforts, companies can effectively minimize disruption, optimize resource utilization, and maintain a competitive advantage in their respective markets.

The Importance of Smooth Operation of Silicon-Steel Cross-Cutting Line

The importance of ensuring the smooth operation of cross-cut silicon steel cannot be oversized, as any disruption to its functionality could lead to serious setbacks in production planning and increased operating expenses. Always maintain the best performance level can not only increase production but also ensure consistent product quality, in line with strict industry standards.

To achieve this goal, continuous monitoring and strict adherence to meticulous maintenance plans are essential. Regular checks can help detect potential problems before they escalate to significant ones, allowing for prompt intervention and minimizing downtime. Furthermore, active maintenance practices such as lubrication, calibration checks and component replacement help to maintain the efficiency and reliability of these tangents.

In addition, smooth operation is essential to ensure seamless integration into a broader production process. It supports operational continuity by reducing the risk of unexpected failures, thereby increasing overall productivity and efficiency. By prioritizing the smooth operation of lateral tangents of silicon steel, the company can not only optimize its manufacturing capacity, but also maintain its reputation for consistently delivering high-quality products.

Common Challenges in Maintaining Silicon-Steel Cross Cutting Line

· Part wear: The cross tagline of silicon steel involves complex machinery with many moving parts, such as rollers, guide rails and cutting mechanisms. These parts wear over time with friction, stress, and operational loads. If used continuously without proper maintenance, it causes accelerated degradation that affecting the accuracy and effectiveness of tangents. Regular inspection and timely replacement of worn parts are essential to mitigate this challenge and extend the service life of the equipment.

· Alignment problem: Alignment plays a vital role in the smooth operation of the silicon steel transverse tangent line. Misalignment of the roller or guide rail can lead to uneven material processing, resulting in inaccurate size and product defects. Factors such as thermal expansion, mechanical vibration, or improper installation can all cause alignment problems over time. Solving the alignment problem requires precise adjustments and regular re-alignment checks to ensure consistent and accurate processing of the material along the tangent line.

· Maintenance of electrical and control systems: Silicon steel cross-tangents rely heavily on complex electrical and control systems to adjust the speed, tension, and cutting parameters during operation. These systems are vulnerable to electrical failures, software failures, and sensor inaccuracies, and, if not addressed promptly, could disrupt production continuity. Periodic calibration, software updates, and diagnostic checks are essential maintenance tasks to maintain the reliability and responsiveness of these critical control systems.

Effective Maintenance of the Impact of the Silicon-Steel Cross Cutting Line on Operational Efficiency

In addition to ensuring the smooth operation of these critical systems, active maintenance strategies can also help streamline production processes and reduce operational disruptions. By pre-identifying and addressing potential issues such as component wear, alignment differences, or electrical failure, the company can maintain a consistent manufacturing output and meet stringent quality standards.

For example, Hengli's strict maintenance method not only guarantees the integrity of the equipment, but also enables customers to optimize their operational capabilities. Through periodic inspection, preventive maintenance planning, and responsive troubleshooting, Hengli ensures that its silicon steel crosscutting machine operates at optimal performance. This commitment not only minimizes the risk of unintended downtime, but also improves productivity and enabling customers to maintain their competitive advantage in the marketplace.

Take Active Maintenance Thinking to Achieve Sustainable Success

In today's fast-paced industrial environment, having an active maintenance mindset is critical to sustainable success. Companies that place maintenance as a strategic priority will be prepared for long-term growth, profitability, and operational resilience. By working with Hengli and harnessing its expertise in maintenance excellence, businesses can cope with the complexity of modern industry with confidence because they know their operations are in the hands of competent people.

Conclusion

In short, the importance of maintenance to maintain the smooth operation of silicon steel cross tangent line cannot be overized. By investing in active maintenance practices and working with industry leaders such as Hengli, companies can ensure the reliability, efficiency, and service life of their equipment, ultimately becoming successful in today's competitive environment. Embrace the power of maintenance, unleash operational excellence, and drive your business toward a future of continued growth and innovation.

The above briefly introduces the importance of maintaining silicon steel cross cut line, if you want to know more or want to buy silicon steel cross cut line, welcome to contact us.

In the rapid development of manufacturing technology, Hengli stands out as a reliable silicon steel cutting lines manufacturer and wins a reputation with its commitment to innovation, precision and customer satisfaction as the industry's preferred supplier seeking cutting-edge solutions for precision cutting and molding processes.

In the field of silicon steel shear line, Hengli has become a trusted ally of the industry in pursuit of precision, innovation and operational excellence. With cutting-edge technology, customized solutions, and a commitment to security and support, Hengli sets the standard for manufacturing reliability. Choose Hengli as your precision partner to experience the difference that innovative rotating vibration shear lines bring in your manufacturing process.