The Science Behind Coil Straightening: How It Works

In the world of metalworking, coil straightening is a critical process to ensure precision and quality in metal products. At Hengli, we pride ourselves on our advanced technology and deep understanding of the science behind this important process. By delving deeper into the intricacies of coil straightening, we can appreciate the meticulous engineering that our advanced machines rely on, which sets us apart from the competition in the industry.

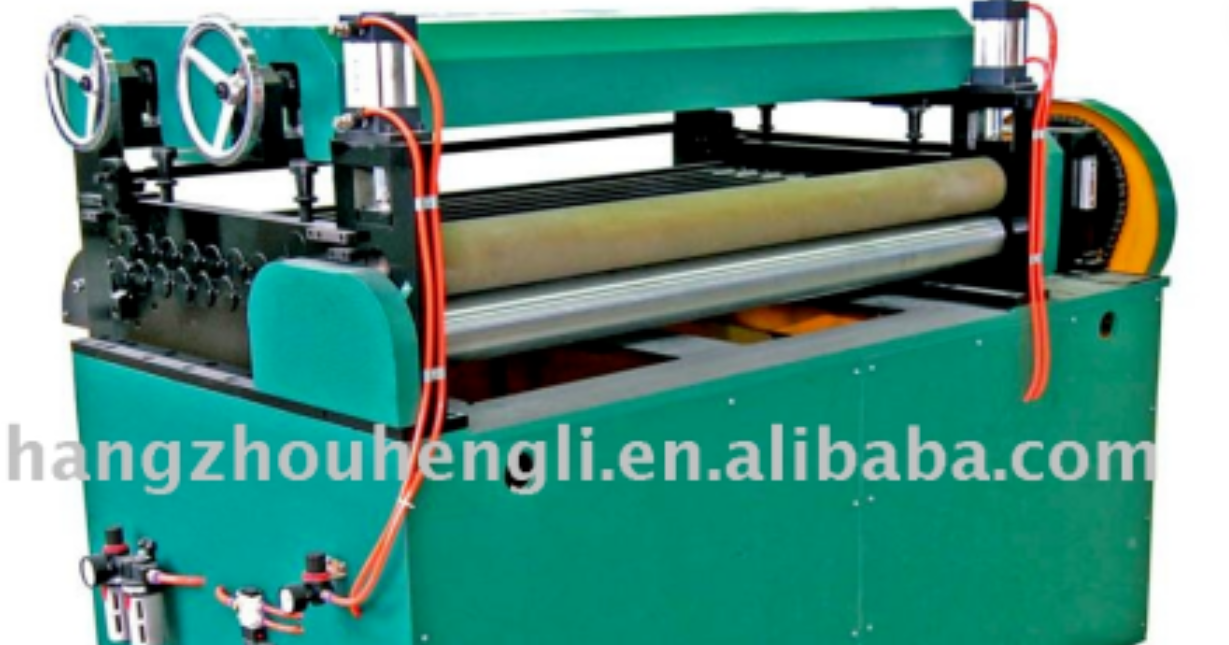

How Coil Straighteners Work

Coil Straighteners are essential tools in the metalworking industry, used to correct deformation and ensure flatness of metal sheets and coils. The most common Coil Straighteners consist of a series of rollers arranged in alternating patterns. Here's a closer look at how the process works:

1. Roller Arrangement

The rollers in a straightener are typically arranged in a staggered or zigzag pattern. This configuration allows the metal to go through a series of bending and straightening actions. The alternating rollers are set at specific angles and distances to apply consistent pressure across the entire width of the metal strip.

2. Feeding the Metal

A metal coil or sheet is fed into a coil straightener. As the metal coil or sheet enters the straightener, the rollers grab the metal and begin to pull it through the machine. The feeding process is carefully controlled to ensure that the metal is processed evenly without causing additional stress or deformation.

3. Cold Working Process

The straightening process is called "cold working" because it is performed at room temperature without heating the metal. Cold working involves the deformation of metal under pressure, thereby changing its internal structure. This is achieved by passing the metal through rollers, which repeatedly bend and flex the metal.

4. Redistribute Pressure

As the metal passes through the rollers, the alternating bending action redistributes the stresses within the metal. These stresses that originally caused the metal to deform are equalized and neutralized. The rollers apply controlled pressure, gradually straightening the metal by forcing it into a uniform, flat shape.

5. Adjustable Rollers

Coil straighteners are often equipped with adjustable rollers, allowing the operator to fine-tune the amount of pressure and the angle of the rollers. This customization ensures that different types and thicknesses of metal can be straightened effectively. Adjustments also help accommodate different degrees of initial deformation.

6. Yield and Quality Control

After the metal passes through the Coil Straightener, it becomes a flat, stress-free sheet or coil. The straightened metal is then quality checked to ensure it meets specifications for flatness and uniformity. Any residual stresses or minor defects can be addressed with additional passes or adjustments to the roller settings.

Key Components of Coil Straighteners

- Entry and exit guides: These components ensure that the metal enters and exits the straightener at the correct angle.

- Work Rollers: These rolls interact directly with the metal, applying the necessary force to straighten it.

- Support Rollers: Located behind the work rolls, they provide additional support to prevent deflection and ensure consistent pressure.

Applications of Coil Straighteners

Automotive Manufacturing

In automotive manufacturing, Coil Straighteners play a vital role in ensuring the accuracy and reliability of high-precision metal parts. Components such as chassis components, suspension systems, and body panels must meet strict straightness and flatness standards to ensure vehicle safety and performance. Any deviation in these components can lead to misalignment, increased wear, and potential safety hazards. Coil straighteners help produce these components with the necessary precision, reducing the risk of defects and ensuring that vehicles meet strict industry standards.

Construction

In the construction industry, the straightness of structural components is critical to the stability and integrity of buildings and infrastructure. Structural steel beams, columns, and rebar must be uniformly straight to ensure they can properly support loads and fit together as intended during assembly. Coil straighteners are used to process these materials, helping to prevent issues such as warping or bending that can compromise the structural integrity of a building project. Precise straightening ensures that materials perform reliably under pressure and adhere to safety regulations.

Electronics

The electronics industry relies on Coil Straighteners to produce thin sheets of metal used in a variety of electronic devices. These sheets are often used in components such as circuit boards, connectors, and housings. Even small imperfections or deviations in the metal can affect the functionality and performance of electronic devices, leading to potential malfunctions or failures. Coil Straighteners help achieve the precise flatness required for these components, ensuring that electronic devices operate efficiently and reliably while meeting the high standards of modern technology.

Conclusion

The science behind coil straightening is a complex interplay of physics, engineering, and materials science. At Hengli, we leverage deep expertise and advanced technology to provide superior straightening solutions that meet the highest standards of quality and precision. By understanding and mastering the intricacies of this process, we ensure that our customers receive the best products for their needs. If you want to know more or are looking for a coil straightening machine manufacturer, please contact us.

Hengli is a professional coil straightener equipment manufacturer. Hengli Group is a leading domestic industrial automation equipment manufacturer, focusing on high-end industrial automation equipment manufacturing. Its main products have a world-leading technology and are widely used in automobile manufacturing and parts processing, steel metallurgy processing, electricity, metal packaging and other pillar industries of the national economy. The company is determined to become a technological pioneer and market leader in the metal carpet forming industry, adhere to innovation, build brands, and revitalize China's equipment manufacturing industry.