How to Choose the Right Slitting Machine?

In the metalworking industry, selecting the right slitting machine is crucial for improving production efficiency and reducing costs. With a wide variety of slitting machines available, each offering different features, it can be confusing for companies to choose the most suitable one. This in-depth guide, based on HengLi's experience, will help you make an informed decision when selecting a metal sheet slitting machine.

1. Define the Type and Thickness of Material

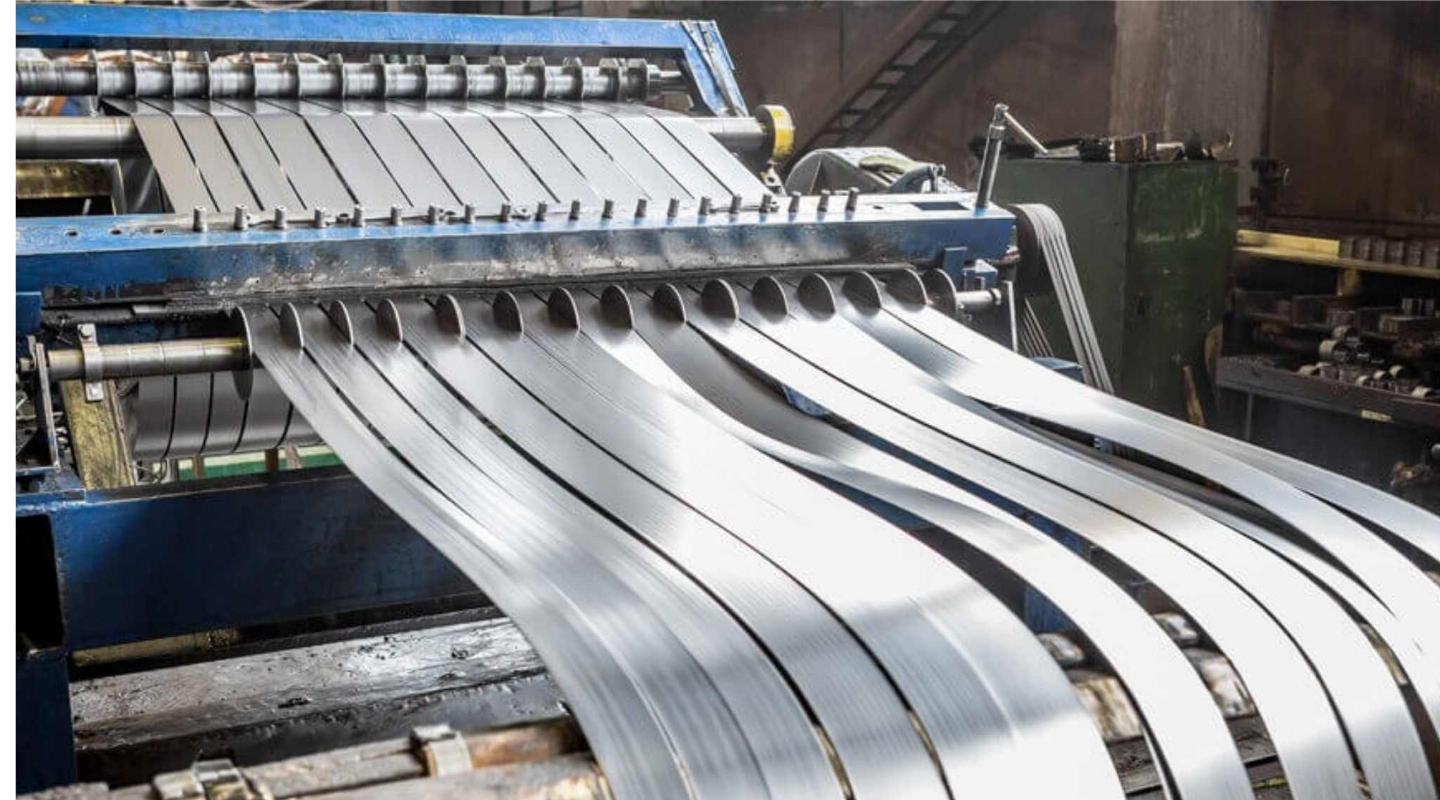

The first step is to clearly define the type and thickness of the metal sheet you will be processing. Different metals, such as carbon steel, stainless steel, aluminum, and galvanized sheets, have distinct properties like hardness and ductility, which require selecting the corresponding slitting machine type. HengLi offers various slitting machines capable of processing a wide range of metal sheets, including cold/hot rolled carbon steel, tinplate, and stainless steel, with thickness ranges from thin to thick sheets.

2. Determine the Cutting Width and Precision Requirements

Next, determine the required cutting width and precision. The cutting width refers to the width of each steel strip after slitting, while precision indicates the acceptable tolerance range of the steel strip width. HengLi's high-precision slitting machines can be customized to meet specific cutting widths and ensure high precision, fulfilling the production needs of different products.

3. Consider Production Efficiency and Automation Level

Production efficiency and automation level are also crucial factors in selecting a slitting machine. If large-scale production is required, then a high-speed slitting machine is the best choice. HengLi's slitting machines use advanced control systems to achieve high-speed, stable cutting, significantly improving production efficiency. Additionally, we offer various levels of automation solutions based on customer requirements, including automatic feeding, unloading, and packaging systems, further enhancing efficiency and reducing labor costs.

4. Focus on Equipment Stability and Reliability

The stability and reliability of the equipment directly affect production continuity and product quality. Choosing reliable and high-performance slitting machines can reduce equipment malfunctions and maintenance costs. HengLi has years of experience in manufacturing precision slitting machines, and our products undergo strict quality control to ensure high stability and reliability, ensuring long-term, uninterrupted operation.

5. Choose the Right Supplier

Selecting the right supplier is crucial. A good supplier not only provides high-quality equipment but also offers professional technical support and after-sales service. HengLi, as a professional manufacturer of metal processing equipment, offers various types of slitting machines and customized solutions based on customer needs. We also provide a professional technical team to offer comprehensive support and after-sales service to ensure the long-term stability of the equipment.

6. Advantages of HengLi

Wide product range: HengLi offers various slitting machines to meet different customer requirements.

Customized solutions: We can provide tailored slitting machine solutions based on specific customer needs.

Advanced technology: Our high-speed slitting machines use state-of-the-art control systems and processing techniques, ensuring high precision and efficiency.

Reliable quality: Our products undergo strict quality control to ensure high stability and reliability.

Professional service: We have a dedicated technical team that provides comprehensive support and after-sales services.

7. Conclusion

Choosing the right slitting machine requires consideration of multiple factors, including material type, thickness, cutting width, precision, production efficiency, automation level, equipment stability, reliability, and supplier selection. We hope this guide helps you select the most suitable precision slitting machine to enhance your production efficiency and create greater value. Feel free to contact HengLi for professional service and tailored solutions.

The Slitting Line modeled ZJ1250 is suitable for accurately slitting transformer iron core, motor iron core, silicon-steel plat

The equipment is used for slit the cold rolled steel,galvanized steel ,stainless steel,coated steel Aluminum and etc.