How to Choose the Right Double-Sided Slitting Line?

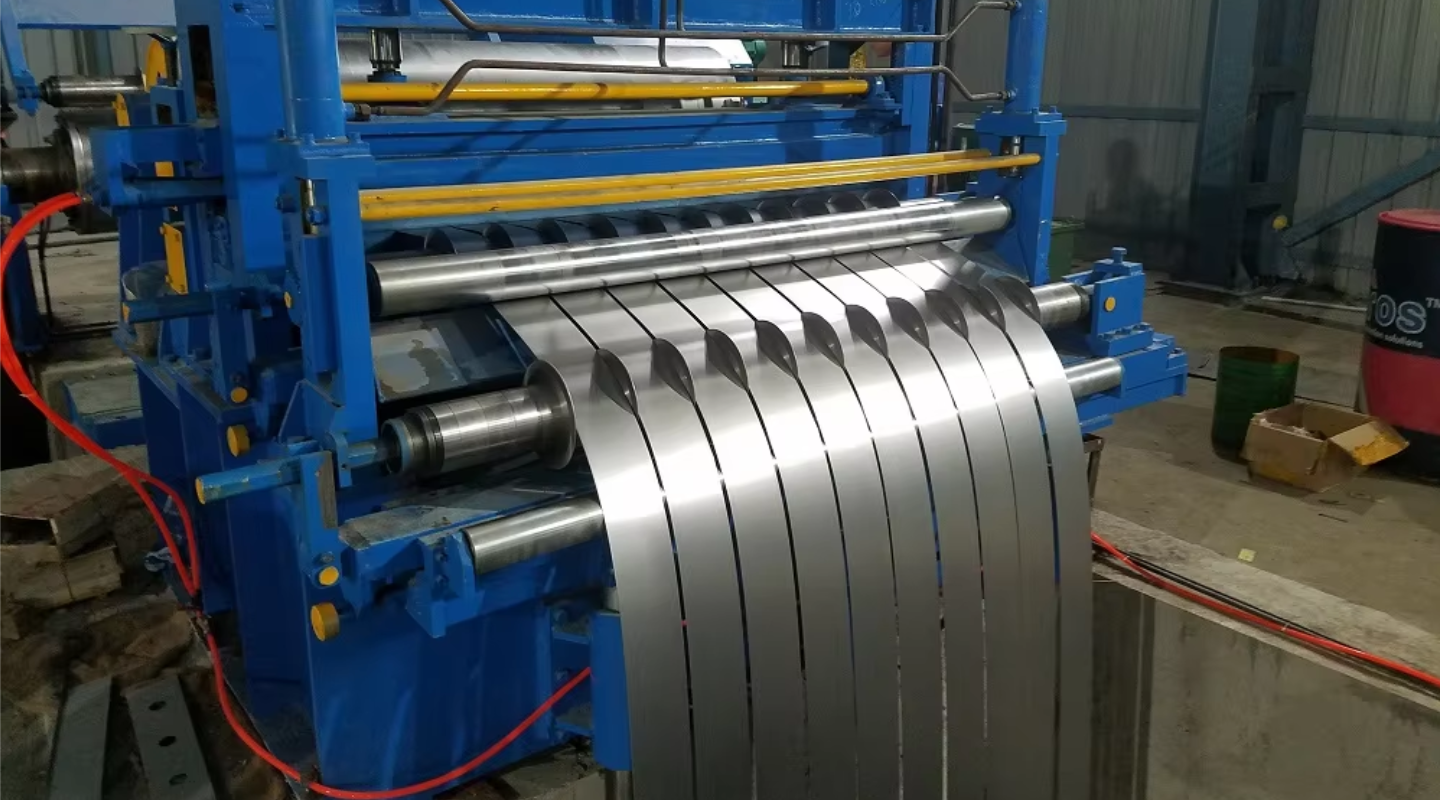

In the metalworking industry, selecting the right double-sided slitting line is essential for improving production efficiency and reducing costs. A double-sided slitting line processes both sides of the sheet simultaneously, significantly increasing output. However, with a wide range of machines available on the market, how can companies find the one that best suits their needs? This article provides a comprehensive guide on choosing the right sheet metal processing equipment, covering aspects such as capacity, material types, precision, automation, and after-sales service.

1. Evaluating Capacity Requirements

The first step is to clearly define your capacity requirements. This includes expected daily production, annual output, and potential future capacity expansion plans. Based on these figures, you can select different specifications and models of metal slitting line equipment. For example, small businesses may opt for compact equipment, while large enterprises will need more efficient, large-scale production lines such as a high-speed precision slitting line.

2. Material Characteristics

The hardness, thickness, and surface coating of materials will affect the tool selection and processing parameters of the duplex slitter machine. You need to clarify the types of materials to be processed, such as:

Cold Rolled Steel / Hot Rolled Steel: These are the most common materials, requiring appropriate tool materials and cutting speeds.

Stainless Steel: Requires higher hardness tools and lower cutting speeds to avoid rapid tool wear.

Galvanized/Color Coated Sheets: Special attention is needed to protect the surface coating, avoiding scratches or peeling.

Silicon Steel Sheets: Used in transformer and motor manufacturing, requiring specialized tools and processes.

HengLi can provide customized tools and processing parameter solutions based on the specific characteristics of your materials to ensure optimal processing results.

3. Precision Requirements

Different products require varying levels of cutting precision. For example, high-precision parts demand higher cutting accuracy, while products with less stringent precision requirements can use equipment with slightly lower precision. You should select a high-speed precision slitting line based on the precision requirements of your product.

4. Automation Level

The higher the automation level, the greater the production efficiency and lower the labor costs. You can select a fully automated slitting line with different levels of automation based on your needs. For instance, a fully automated production line can achieve automatic feeding, cutting, stacking, etc., greatly reducing manual intervention. HengLi offers various automation solutions, customizable to meet your specific requirements.

5. Stability and Reliability of the Equipment

Choosing stable and reliable equipment can reduce downtime due to malfunctions and increase production efficiency. When selecting a metal slitting line equipment, you should consider the equipment's manufacturing process, the quality of key components, and the manufacturer's reputation. HengLi has years of production experience, ensuring stable and reliable product quality.

6. After-Sales Service

A comprehensive after-sales service system is crucial. This includes equipment installation and debugging, operator training, maintenance, and troubleshooting. Choosing a manufacturer that provides excellent after-sales service ensures the long-term stable operation of the equipment. HengLi offers professional technical support and after-sales services to ensure the long-term stability of your equipment.

7. HengLi's Advantages

As a professional manufacturer of metal sheet processing equipment, HengLi provides high-performance double-sided slitting lines and customized solutions based on customer needs. Our advantages include:

Rich Experience: Years of industry experience, and a deep understanding of customer needs.

Advanced Technology: Employing advanced processing technologies and control systems to ensure product quality.

Customized Services: Offering customization of tools, parameters, and automation configurations based on customer requirements.

Comprehensive After-Sales Service: Providing professional technical support and after-sales services to ensure long-term stable operation.

8. Conclusion

Choosing the right double-sided slitting line is a complex process that requires consideration of multiple factors. By carefully evaluating your needs and following the guidelines provided in this article, you can find the metal slitting line equipment that best suits your business, enhancing production efficiency, reducing costs, and improving competitiveness. Contact HengLi today for expert advice and services.

For can-making company to vertically and horizontally slit tinplate precisely.

The Slitting Line modeled ZJ1250 is suitable for accurately slitting transformer iron core, motor iron core, silicon-steel plat