The Ultimate Guide to Selecting Double-Sided Slitting Machines in 2025

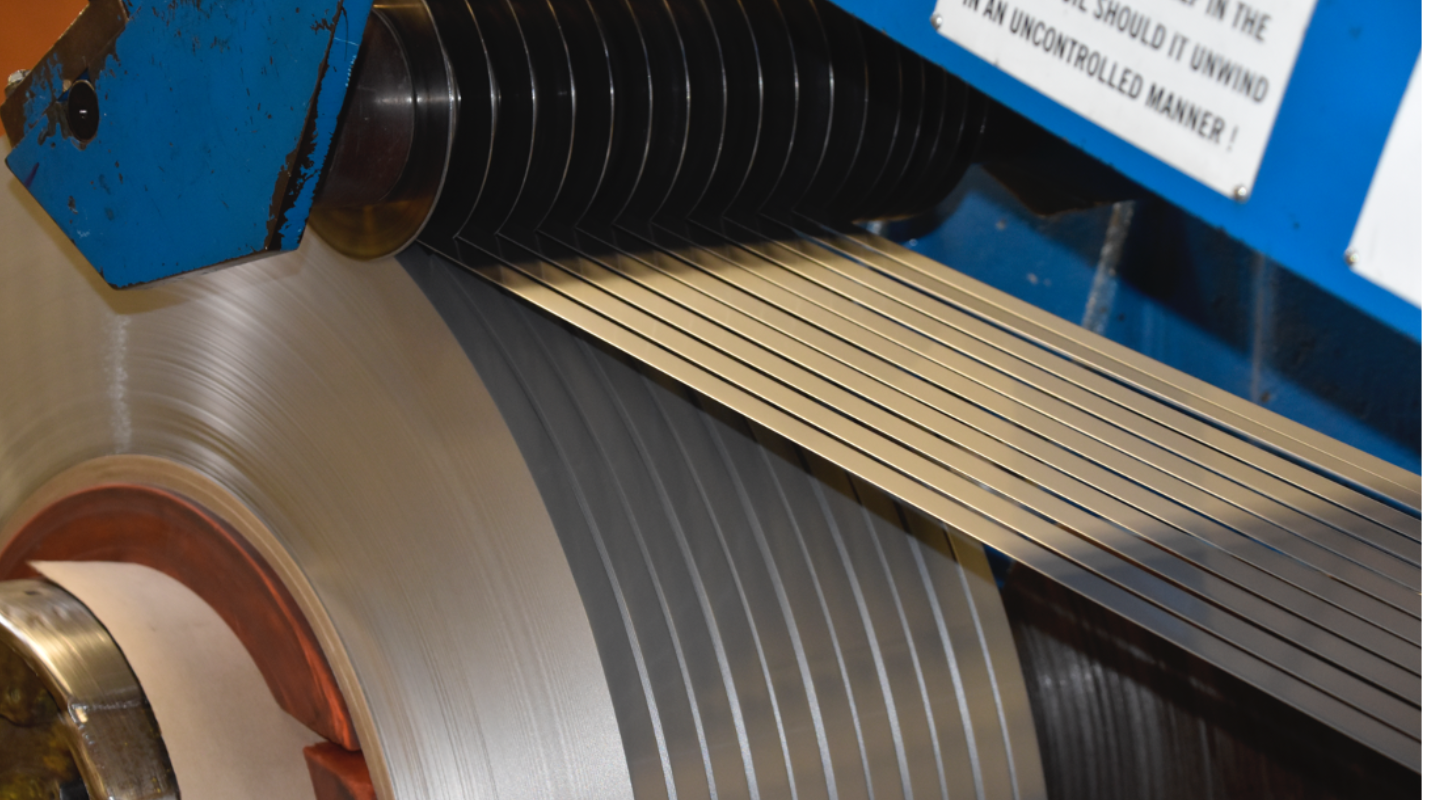

In the metal processing industry, slitting machines are crucial for improving production efficiency and reducing material waste. Among these, double-sided slitting machines have become the top choice for businesses aiming for high efficiency and precision, as they allow for simultaneous dual-side cutting. However, with a wide range of options available, choosing the right automatic duplex slitter to meet your needs can be challenging. As experts in metal sheet cutting and forming automation equipment, Hengli brings you the ultimate guide to selecting duplex slitter machines in 2025, combining years of industry experience to help you make the perfect match and lead the future!

Why Choose an Automatic Duplex Slitter? Key Advantages

Before diving into selection, let's first understand the key advantages of automatic double-side slitting machines:

Double Efficiency: Dual-side cutting increases production efficiency, doubling the output of traditional single-side slitting machines.

Higher Precision: Simultaneous dual-side slitting ensures cutting accuracy, reducing material waste. This is why a high-precision slitting machine is often preferred in precision-driven industries.

High Automation: This can seamlessly integrate with automated production lines for unmanned production, a key feature of the automatic duplex slitter.

Wide Applicability: Suitable for various metals such as cold-rolled steel, hot-rolled steel, stainless steel, and aluminum, making it versatile for many manufacturing environments.

Key Selection Criteria: Five Core Factors

1. Material Type and Thickness:

Material Type: Different materials, such as cold-rolled steel, hot-rolled steel, stainless steel, and aluminum, have varying tensile strengths and elongation rates, affecting machine requirements. For example, high-strength steel requires higher cutting force, while aluminum needs more precise tooling for best results in a duplex slitter machine.

Material Thickness: The cutting ability of the machine directly affects its application. Choose a machine based on the thickness of the materials you process, ensuring it aligns with the capacity of your duplex slitter.

Hengli Suggestion: Clearly define the primary materials and thicknesses for your operation to choose a machine with the appropriate cutting capacity. For example, if you're mainly processing 4mm thick hot-rolled steel, select a machine with a cutting capacity above 4mm.

2. Cutting Precision and Speed:

Cutting Precision: Precision directly affects product quality. Choose high-precision slitting machines with advanced control systems to meet your cutting accuracy needs.

Cutting Speed: Slitting speed can range from low to high, directly affecting production efficiency. Look for machines with adjustable speeds to tailor operations to various materials and thicknesses, which can be a key feature of an automatic duplex slitter.

Hengli Suggestion: Both cutting precision and speed are critical performance indicators. When selecting, balance these factors for the best value. For example, if precision is a higher priority than speed, opt for a slower but more precise duplex slitter machine.

3. Automation and Intelligence Level:

Automation Level: The more automated the machine, the less manual intervention is required, which boosts production efficiency. Choose automatic duplex slitter machines with automatic feeding, alignment, and discharge features for a fully streamlined process.

Intelligence Level: Higher intelligence means easier operation and maintenance. Look for duplex slitter machines equipped with remote monitoring, fault diagnosis, and data analysis functions.

Hengli Suggestion: With the ongoing development of smart manufacturing, prioritize machines with higher automation and intelligence levels. For 24-hour production, an automatic double-side slitting machine is the optimal choice.

4. Tool Material and Longevity:

Tool Material: The material of the tool affects both cutting quality and tool life. Alloy steel is suitable for cutting standard steel, high-speed steel for high-strength steel, and carbide for stainless steel and aluminum.

Tool Life: Longer tool life reduces production costs. Machines with replaceable or repairable tools can lower tool replacement expenses.

Hengli Suggestion: As tools are a core component of the duplex slitter machine, focus on the quality of the materials and tool life when selecting. For stainless steel processing, choose machines with carbide tools.

5. Brand Reputation and After-Sales Service:

Brand Reputation: A reputable brand ensures quality and performance. When choosing an automatic duplex slitter, a trusted brand can make a significant difference in ensuring long-term efficiency and reliability.

After-Sales Service: A comprehensive after-sales service system ensures timely technical support and maintenance services to keep the machine running smoothly.

Hengli Suggestion: When selecting a duplex slitter, prioritize brands with a strong reputation and a reliable after-sales service network.

Hengli Double-Sided Slitting Machines: Your Ideal Choice

Hengli has years of experience in metal sheet cutting and forming automation equipment, offering high-performance double-sided slitting machines with the following advantages:

1. High Precision: Advanced control systems and high-precision tools ensure top-notch cutting accuracy, perfect for high-precision slitting machines.

2. High Efficiency: Double-side slitting increases production efficiency by two times compared to traditional single-side machines.

3. High Automation: Seamlessly integrates with automated production lines for unmanned operation, making it an ideal solution for those looking to integrate automation with automatic duplex slitters.

4. High Reliability: Built with high-quality materials and excellent craftsmanship to ensure long-term stability and reliability.

5. Customization: Machines can be tailored to meet specific customer needs, ensuring optimal performance for various applications.

Selection Process: Hengli Experts Provide Full Guidance

1. Needs Analysis: Clarify your cutting requirements, including material types, thicknesses, precision, and speed.

2. Solution Design: Hengli experts will design a tailored slitting solution based on your needs.

3. Equipment Selection: With expert guidance, choose the best automatic duplex slitter for your operations.

4. Installation and Debugging: Hengli engineers will provide professional installation and commissioning to ensure optimal machine performance.

5. After-Sales Service: Hengli offers a robust after-sales service system, providing timely support and maintenance.

Conclusion

Choosing the right double-sided slitting machine is key to improving production efficiency and reducing costs. Hengli, with its expertise, high-quality products, and comprehensive service, helps you select the perfect machine for your business. Contact Hengli today to receive professional advice on duplex slitter machine selection! Visit Hengli's website to learn more about our products and services.

For can-making company to vertically and horizontally slit tinplate precisely.