Industry Trend: The Development and Future Outlook of Shear Line Technology

Shear lines are a crucial part of the metal sheet processing production line, and technological innovations directly affect the efficiency, quality, and competitiveness of the entire industry. Understanding the development trends of shear line technology is critical for metal processing companies in formulating long-term strategies. This article explores the latest trends in shear line technology and provides insights into its future, aiming to offer valuable references to industry peers.

1. Current State of Shear Line Technology

At present, shear line technology is undergoing rapid development and transformation. Automation levels are continuously improving, but there is still room for enhancement. Precision has become a standard, but overcoming accuracy limitations remains a key challenge. The demand for flexible production is increasing, requiring higher adaptability from shear lines. Meanwhile, smart technologies are starting to be applied, but they are still in the exploratory phase.

2. Five Key Trends in Shear Line Technology

Smart Technology:

Trend Analysis: Smart technology is the core direction for the development of shear line technology. By integrating sensors, the Internet of Things (IoT), big data analytics, and artificial intelligence, shear lines can achieve real-time monitoring, intelligent diagnostics, optimized control, and predictive maintenance. Smart shear lines can automatically adjust parameters, optimize cutting paths, improve production efficiency, enhance product quality, and reduce manual intervention and maintenance costs.

Future Outlook: In the future, smart shear lines will possess self-learning capabilities, optimizing their performance based on production data, achieving true smart manufacturing.

Flexibility:

Trend Analysis: Flexibility is key to meeting the demand for multi-variety, small-batch production. Technologies such as modular design, rapid mold-changing systems, online programming, and virtual simulation enable quick switching between different specifications and materials of metal sheets. Flexible shear lines can meet diverse customer needs, improving production efficiency and market responsiveness.

Future Outlook: Future flexible shear lines will enable fully customized production to meet personalized customer requirements.

High-Speed Operation:

Trend Analysis: High-speed operation is a direct means to enhance production efficiency. By optimizing mechanical structures, adopting high-performance servo systems, and using advanced control algorithms, shear lines can increase cutting speed and acceleration. High-speed shear lines shorten production cycles, improve output, and reduce production costs.

Future Outlook: Future high-speed shear lines will achieve ultra-fast cutting speeds, greatly enhancing production efficiency.

Precision:

Trend Analysis: Precision is essential for ensuring product quality. High-precision sensors, control systems, and advanced compensation technologies are used to improve cutting accuracy and surface quality. Precision shear lines meet the stringent requirements of high-end manufacturing fields for product precision and quality.

Future Outlook: In the future, precision shear lines will achieve micron-level cutting accuracy, meeting the needs of micro-nano manufacturing.

Eco-Friendly and Sustainable:

Trend Analysis: Green manufacturing is a necessary choice for sustainable development. Using energy-efficient materials and processes, optimizing energy utilization, and reducing noise and waste emissions, eco-friendly shear lines help reduce environmental pollution and increase corporate social responsibility.

Future Outlook: Future eco-friendly shear lines will achieve zero emissions, becoming truly environmentally friendly equipment.

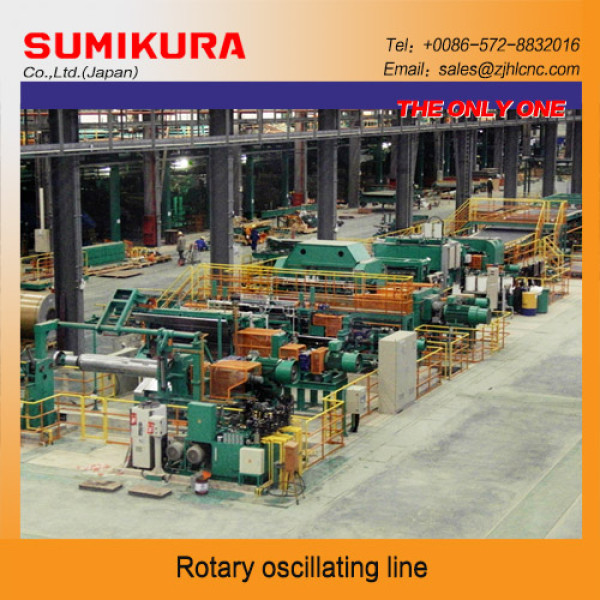

3. Hengli CNC's Role in Shear Line Technology Development

As a leading company in metal sheet cutting and forming automation equipment, Hengli has consistently kept up with industry development trends, continuously innovating and developing new technologies and products. The company has made advancements in smart, flexible, high-speed, precision, and eco-friendly technologies, aiming to provide customers with more efficient, intelligent, and environmentally friendly shear line solutions.

4. Future Outlook

In the future, shear line technology will evolve towards smart, flexible, high-speed, precise, and eco-friendly solutions. With the continuous emergence and application of new technologies, shear lines will no longer be simple cutting devices but integrated intelligent manufacturing systems. Hengli will continue to invest in R&D, working together with industry peers to advance shear line technology and contribute to the transformation and upgrading of the metal processing industry.

Contact Hengli to learn more about the development trends and solutions for shear line technology!

Material: Silicon-steel, tinplate, strip steel and aluminum strip, etc

Slitting thickness: 0.2-1.5mm

Slitting width: ≥30mm

include pinhole detector, inspection mirrors, upender, flying type cutting, 100 sheets/min, 3 stackers