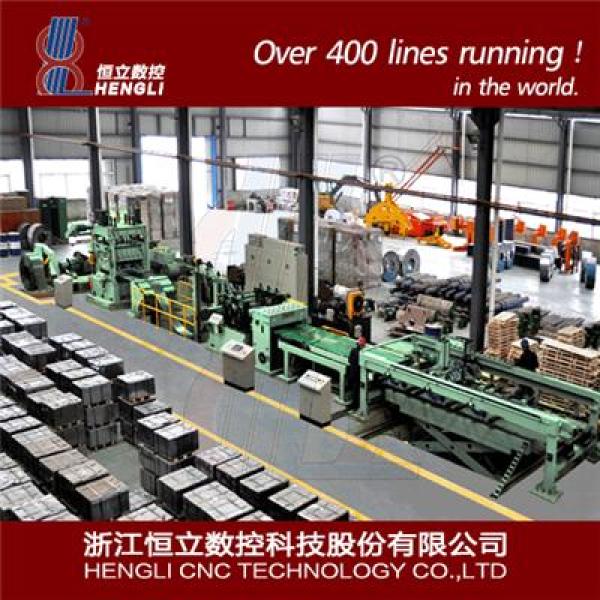

Hengli CNC TechnologyCo., Ltd was established in 2005, which is a national high-tech enterprisespecialized in researching and manufacturing of high-end industrial auto equipments,and is one of the main suppliers of Chinese metal plate cutting, formingautomation equipments. In April 2014, Hengli successfully listed in the new OTCmarket (stock code 430676) and became the first listed company in Huzhoucity.

Categories

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line

High speed cut to length line

| Categories | Cut to Length Line2 |

|---|---|

| Brand | Hengli, SUMIKURA |

| Update Time | Apr 19,2025 |

Detail Information

I.Technical Data for KJB series

Material cutting | Cold roll steel, galvaniz roll, stainless steel , aluminum | |

Item | Unit | Range |

Thickness | MM | 0.3-2, 0.5-3 |

Width | MM | 1250,1500,2000 |

Load weight | T | 15 |

Leveling precision | MM/M2 | 1 |

Measuring precision | MM/M | 0.5 |

Line speed | M/MIN | 40,60 |

Power | KW | 95 |

II. General Induction of cut to length line

Cut To Length Lines can do uncoiling, leveling, measuring, cross-cutting to length and stacking work. It mainly includes uncoiler, leveler, measuring encoder, shearer, conveyor, stacker, hydraulic system, pneumatic system and electrical system, etc., the line can make sure of accurate feeding and shearing. It can be widely used in cold or hot rolling carbon steel, tinplate, stainless steel and all the other kinds of metal materials with surface coating.

Cut to length line is controlled by NC servo system. It has PLC controlled the length measurement. The information of length, shearing numbers and speed can be input to the PLC systems. When the need shearing number is reached the line can stop automatically. The line speed can be adjusted, It has a encoder with high precision, and whole line can work automatically and operate easily, smooth sheet can be made.

III. LIST OF EQUIPMENTS UNDER SCOPE OF SUPPLY:

1. Coil car

2. Decoiler

3. peeler table

4. precision leveler

5. Loop Bridge

6. Side Guide Roller

7. Servo feeder

8. Shearing Machine

9. Conveyor table

10. stacking table

11. lifting table

12. Hydraulic Systems

13. Pneumatic Systems

14. Electrical System PLC Control

Review

- Loading...

Do you need any help?

We can help you find what you want! Talk to our sales team members and benefit from their expert advice

- *Title

- *Content

Categories

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line